Simulation for Factory Design

Be confident in your factory designs with computer modelling

We create a simulation of your factory design powered by real data. This helps the Engineering team validate their designs and resolves concerns over bottlenecks and inefficiencies.

Arrange a free demo

What is Simulation for Design?

Simulation is used to create a dynamic model of your engineering design. It is great for capturing and assessing your design at all stages of the development process from concepts to detailed engineering. The model is constructed using state-of-the-art simulation software in which a process map is created from constituent elements such as activities, resources, materials, and layouts to create a realistic and accurate digital representation of the process.

Digital Twin

The model is built in a similar way to how you would construct a process flow diagram with different activities or unit operations connected to show the flow of work. Rather than being a static tool, the digital twin brings your design to life by dynamically simulating the flow of work through the process. This allows you to identify both the status and performance of plant equipment at any time of production..

Discrete events simulation software

The software uses Discrete Event Simulation, this means that operations occur as a sequence of events in time. This allows the model to account for constraints, resources availability, complex interactions and routing. By using engineering information and historic production data, high levels of accuracy and insight are achieved. Once the model is complete you can run as many different scenarios as you want, plus you can update the model at any time with new information and design developments.

The software also allows you to test out a variety of events such as breakdowns, so you can demonstrate the design resilience and accurately evaluate time critical processes. This function can be invaluable to support design reviews such as HAZOPs of d-FMEAs.

Data analytics

The software automatically collects time-based performance data for all elements of the design. These can include energy usage, waiting times, labour utilisation, materials consumed or any other metric you are interested in. This means that you can analyse the performance of each element individually at any time you choose.

Having this dynamic data at your fingertips gives you incredibly powerful analytical capability to provide accurate insight and foresight into your design. Which parameters you want to control and measure are entirely your choice. Experiments can be created where multiple scenarios are ran sequentially so you can identify the optimal performance conditions in a matter of minutes.

Production Support 56 were brought in late to the project and quickly produced an accurate simulation of our design which was run with the client historic production data. They proved the design met all our clients’ requirements and helped us optimise and removed significant costs. The client loved the model demonstration and subsequent what-if games.

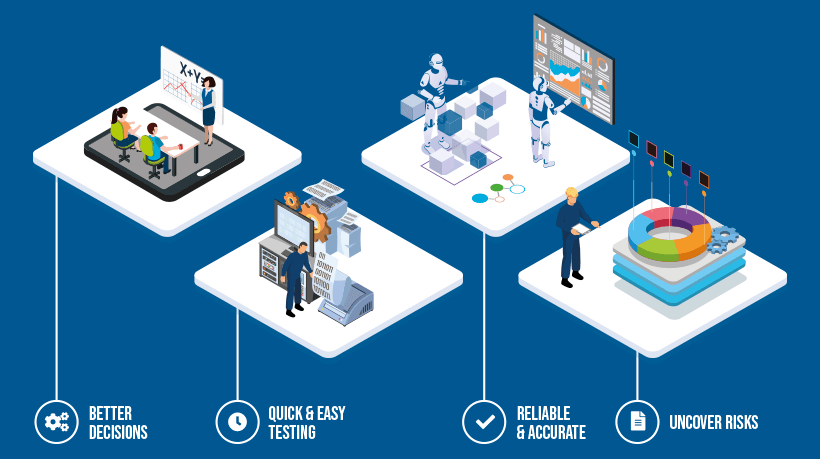

The Benefits of Simulation for Design

Clear Data Analytics

Since the model is constructed using real process data, critical design decisions are made using data based evidence rather than instinct or hunches.

Accurate Operational Costs

Your model tracks labour, energy and material usage, making it easy to monitor and determine accurate costs and carbon footprint for many different scenarios.

Identify Design weaknesses

Your model and inbuilt analytics means improvement opportunities can be immediately identified and quantified. Potential solutions can be rapidly tested and the outcomes evaluated.

Reduce Design Risk

Your design can be thoroughly stress tested, developed and optimised. Stakeholders can interrogate your design, building confidence and establishing consensus.

Clear Process Understanding

Your simulation is a visual representation of your design providing clarity and understanding to complex operations. Your designs are brought to life to see the future in action.

De-Stress Decision Making

Avoid the unnecessary stress and worry over critical decisions. Experimenting with your model can uncover hidden risks long before any costly implementation.

Why use Production Support 56?

At production support 56 we have decades of experience working with Engineering teams to design and develop production processes. We have been using Modelling to support design justifications for over ten years. We first used simulation to justify capital expenditure on expensive process equipment. The simulation demonstrated that the equipment had the right capacity for the design scope and resulted in high utilisation and good value for money. We have a strong background in process development and found that modelling employs the same types of skills such as carefully defining the project scope, process mapping, data gathering, data analysis and good communication skills.

We are accredited by Simul8 as a certified solutions provider and use their state of the art software to create and run simulations of your design. This powerful software platform allows us to focus on getting the right information into the model, and more importantly provides the means for producing meaningful analysis.

What is involved?

How to get Started with Simulation for Design

Production Support 56 can support every stage of your project by creating a computer simulation of your production facility or engineering design. The model can be used to validate, optimise and communicate your design at each stage of the project.

To create a simulation, we follow these steps:

- Project Scope- Define the goal and purpose of your model.

- Data collection- Create process maps and collate performance data of your facility or design. Collect historic production or sales forecasting data.

- Model- Construct a bespoke computer model using state of the art manufacturing simulation software.

- Validate and test- Run your model with the stakeholders to check validity. Run scenarios with stakeholders to interrogate and evaluate the design.

- Report- Collate and report out key findings and information from model.