Simulation in manufacturing isn’t new. However, many believe it’s only for large-scale companies, requiring huge investment in IT to produce complicated and futuristic models of their operations. The good news, however, is that this is not the case and simulation can be used by organisations of any size to find ways to streamline and improve them.

Production support 56 are here to show that manufacturing simulation can be used by any sized company and can deliver real and practical results in days rather than months.

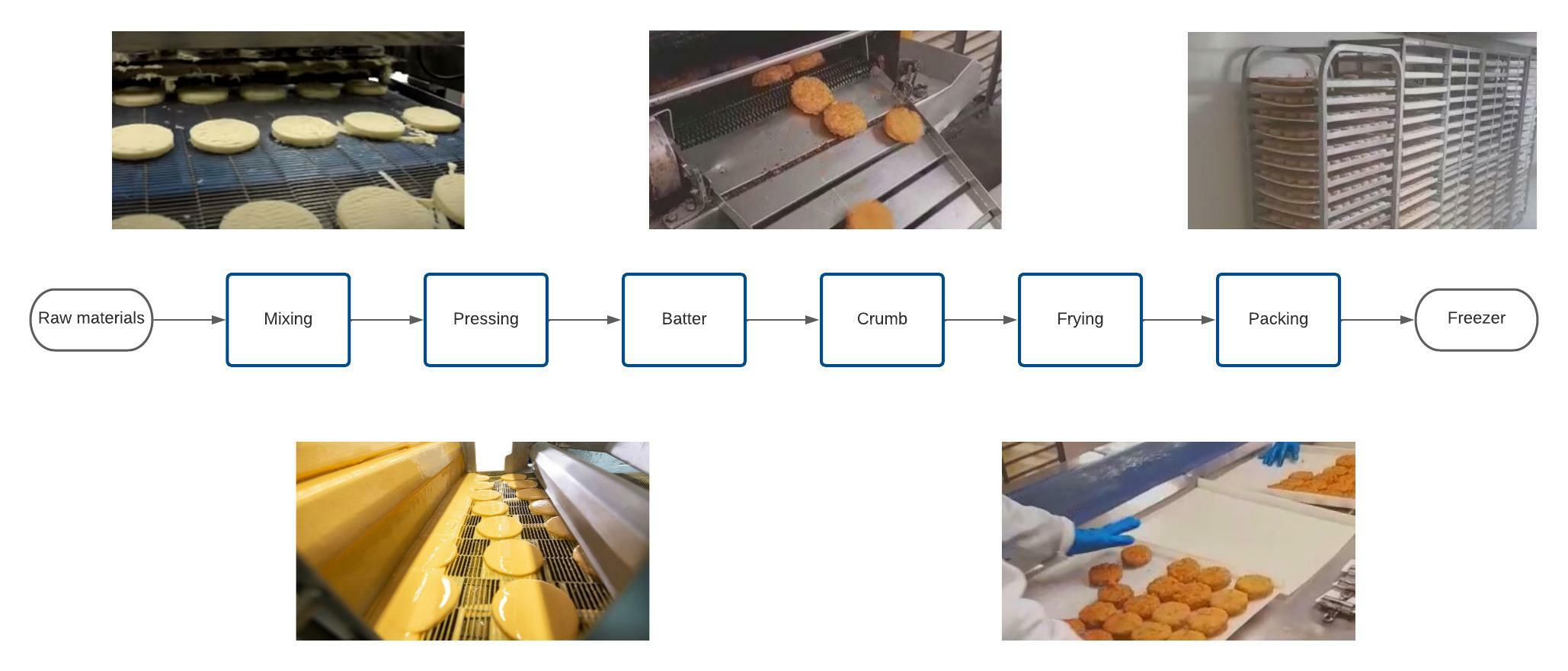

The new owners of Norvik foods, based in Lincolnshire embraced the use of manufacturing simulation to assess the current line performance, test out process improvements to remove bottlenecks and evaluate the benefit of investment in new process equipment. The team at production support 56 helped by constructing a dynamic computer model of their fishcake production line using real operational data which enabled the Norvik management team to test and evaluate a variety of process improvements.

Watch the case study video here

You can also find out more about this project as featured in a recent article published by Smart Industry.

Norvik Foods uses smart simulation to increase line output by 55%

If you are looking to make improvements or invest in your production line and are unsure which changes will which will bring the biggest benefit, get in touch to arrange a demo and to see how manufacturing simulation can help you make the smart decision.

Find out more about our manufacturing simulation service here Simulation for improvements