Last weekend my wife and I took the rare opportunity to go out for dinner. With a babysitter sorted, glad rags on, we were both looking forward to some well-earned quality time, some good food and our favourite little tipple at a well-known and highly recommended local restaurant.

We eagerly arrived in good time and was greeted with warm smiles asking for our reservation. After a couple of minutes searching through piles of notes and scraps of paper, the front of house staff began to look a little flummoxed.

They asked, “when did we make the reservation, who did you speak too? and did you make the reservation online?”

My wife replied that she had rang earlier in the week to make the reservation, and spoke with a polite chap who sent through the email confirmation which we promptly showed her. This added to the bewilderment and so began a series of frantic double checking back through the mountains of loose papers on the counter top and clicking the laptop mouse with fury!

After a few more uncomfortable seconds the polite staff member said “I do apologise but we seem to have lost your reservation, but please don’t worry, we shall squeeze you in somewhere!”

Once seated at our table and our order for drinks order was taken, I noticed that the waiting staff took orders in a variety of ways, some had notepads and pens and other had tablets, (you know the one with the large fruit based logo). After about fifteen minutes we received our drinks, I was looking forward to a nice pint of a local ale which was recommended by the waiting staff, but instead a pink liquid with lots of fruit arrived in front of me. Again, apologies were made and soon I had my chosen pint before me.

Now…..my wife and I have a healthy agreement not to talk shop when we are out relaxing, so I was surprised that after watching her survey the room of the busy waiting staff darting around, the cook rushing around in the open kitchen, and after a few comments about our reservation and drinks mix up, my wife turned to me, smiled and said

“you know what this place needs, don’t you?, a little organisation, isn’t it called 5S or something?”

I replied that I wasn’t going to mention it since its shop talk, but yes I was bursting at the seams with thinking about how appropriate the lean 5s method would be here and how it could really help these poor bewildered and overworked staff. I am sure at some point we have all had experiences like the one my wife and I had, and often see the same confusion and disorganisation at work, at home or the supermarket – in fact pretty much everywhere. We also may proffer solutions with statements like –

‘this place needs organising’ or ‘could do with a bit of a tidy up’ or that ‘staff and management need better training’.

Such statements like these will probably help to improve the situation but I often see such improvements as transient or temporary with a short life span – days, weeks or months may pass – but as sure as oats is oats the inevitable return to the old ways bed back in.

The idea of sustainable improvements which stick and become part of the way we work is what gets me so giddy about the use of 5s. When I am asked to improve a particular process or product with the onus to reduce costs, increase profit, improve efficiency or reduce waste I begin very simply by asking myself – if I was asked to find something could I find and retrieve it within 1 minute? If the answer is no, then my default position before any grandiose improvement project is to get the area organised in such a way to make it easy for anyone to find what they need – like tools, equipment, documents, drinks orders or table reservations!

Very often, the starting point for businesses who wish to embark on a journey of process improvement is making sure the workplace is organised. In Lean Manufacturing there is a simple yet structured method called 5s to achieve this.

Now before I continue – you may of heard of 5S before and say ‘isn’t it just a quick tidy up?’ and you would be partially right, the difference of a quick tidy Friday is that 5s gives structure and sets expected standards to make it easier for everyone to complete their tasks, simply put, to make sure everyone is singing from the same hymn sheet and also that that any improvements last longer than my pint of ale did.

The 5s process improvement tool is a Japanese Lean management philosophy and reputedly originates from the Toyota motor company. There are other techniques, similar in nature, some of which came before like Henry Ford’s CANDO system and some came later like the KonMari method developed by Marie Kondo. The central theme of organising as efficiently and as practically as possible, however remains the same.

The 5s system sets out 5 simple steps for efficient organisation and is a great starting point for facilitating a sustainable continuous improvement culture.

The 5 Steps

- SORT – Remove everything, and I mean everything, which is not required for the job, if in doubt throw it out! If you are unsure then set up a holding area to place things with a strict time limit for people to claim, keep or dispose of the items.

- SET – Place all remaining items in an order of how often they are used, a place for everything and everything in its place. Change the layout of the area if you need to, label where things belong to make it obvious to anybody where they are and also when they are missing!

- SHINE – Yes you’ve guessed it – deep clean the work area , paint if necessary. A clean area makes it easy to spot when things go wrong like leaks, spillages and such like.

- STANDARDISE – Agree with your colleagues and co-workers how can we make sure the first three S’s stay in check? Make simple instructions on how to keep the place clutter free, things in the right order and clean and tidy. Most importantly, keep it simple – do not use ring binders to hold instructions and checklists, a single side of A4 in large lettering an absolute maximum!

- SUSTAIN – Stick to the standards you have all set yourself, check at regular intervals and make improvement no matter how small they seem, check different work areas – get everybody involved including the management.

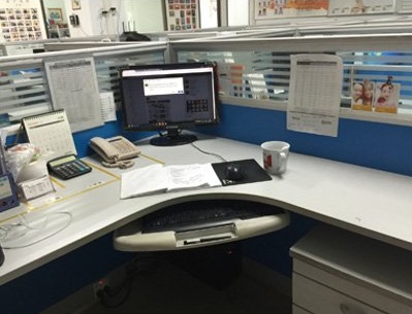

Here are great before and after photos, I am sure everybody has seen an office desk like the one of the left!

There are so many benefits to having a 5S workplace.

- Reduced waste.

- Reduced breakdowns

- Problems spotted early and resolved quickly

- Reduced errors

- Improved safety

- Time saved hunting around for that pesky tool or document.

What I really like is that it gives ownership to everybody who works in the area. It impresses visitors, improves company reputation and above all pleases your customers, especially those who love a good pint of ale!

For many, 5S is the foundation and the beginning of the improvement journey. Once in place, this paves the way for both small incremental improvements and also longer-term strategies for business growth.

My top tips for running a 5S event would be:

- Prioritise the workplace, divide into bite sized areas for each 5S event. Do not try and 5s the entire company, people are far too busy for that.

- Identify who owns the area, not a case of everyone and no none.

- Make a list of tools, equipment, cleaning items required to complete each step.

- Set a schedule for the 5S events and tell people it’s happening.

Needless to say, my wife and I enjoyed a fantastic meal and had a lovely night away from the home. My patient and understanding wife didn’t even roll her eyes when mentioned the value of 5S to the staff.

If you are interested in learning more about 5s or other lean tools to support your improvement projects get in touch or check out our process improvement page.

‘If you want to beat your rivals and need a better fix, supercharge your processes with Production Support 56.’