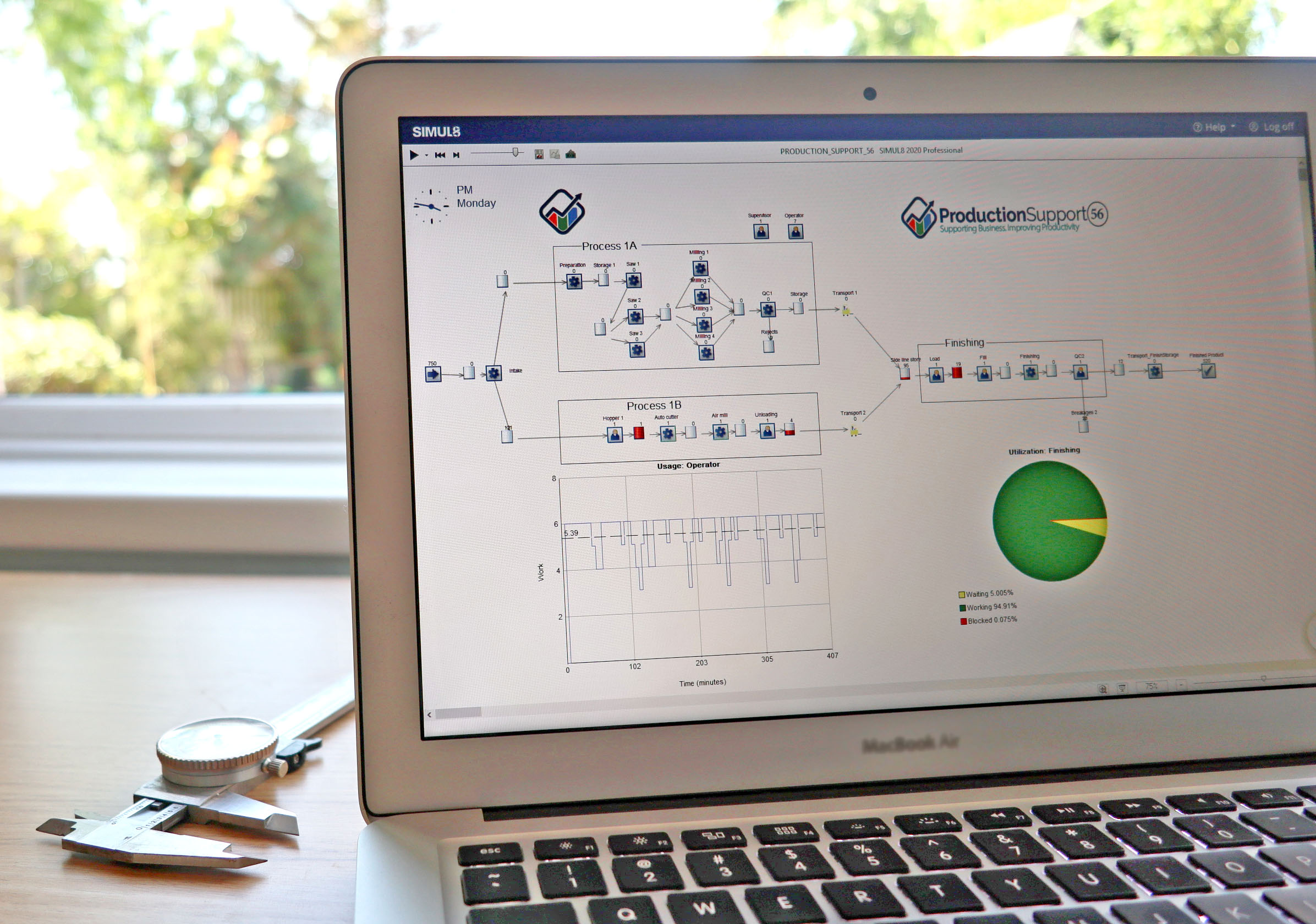

Manufacturing simulation lets you create models of your production processes and supporting systems. It is not just equipment and cycle times, you can include labour, skills, tools, product mixes, shift patterns and complex routing. As long as you can describe your process and decisions you can create a useful model. You can model a concept, a design, or an existing line. Once you have the model you can run multiple scenarios and test out ideas virtually before making permanent changes in real life.

These are my 5 favourite things about manufacturing simulation:

- You can share a model with your colleagues. It lets them see your ideas, your problems, and your solutions. It lets them ask questions, ‘what would happen if we changed this?’ It is much easier to convince people if they can see the idea and interrogate it (especially the finance department ?).

- You can evaluate improvement opportunities. There are often lots of ideas on how to improve a production line, but it is very difficult to evaluate each one. It is even more difficult to evaluate a series of improvements. With a model you can test each idea and combinations of ideas and determine the best sequence of improvements for your line and budget.

- You can develop scale-up plans. You may have some data from working at a smaller scale, some trial data, forecasted sales, some equipment specifications, and spreadsheets with some heroic assumptions. Simulation allows you to piece all the information together along with some best guesses, and create a realistic simulation of your scale-up plan. You can quickly see where you need better data and where you can make improvements.

- You can create a planning tool. A lot of companies are data rich but do not know what to do with it all. With that data you can create a detailed model and do some really useful things. You can run a production schedule through it to determine the lead times or if it is going to cause any bottlenecks. You can use it to plan production around maintenance schedules. You can look at the true cost of expediating a sales order.

- You can investigate process variation. If something goes wrong on your production line you can simulate that scenario and examine the underlying causes. Was it a one in a ten thousand events, or was it always going to happen? With manufacturing simulation, you can model variation and identify a perfect storm, and preferably prevent it from happening.

If you are interested in learning more about manufacturing simulation then take a look at our website or contact me for a demonstration.

‘If you want to beat your rivals and need a better fix, supercharge your processes with Production Support 56.’