Better factory designs

As a Design Engineer your main job is to create factory designs that meet your client’s specifications, the second job is to convince your client you have met their design specifications. Manufacturing simulation is a means to achieve both.

Manufacturing simulation lets you create a model of your factory design. This has the benefit of being able to simulate the actual operation of your design dynamically. Meaning you can look at the plant performance at any time of the operation. This is great for validating your design, identifying weaknesses, and communicating with the stake holders. Overall, it leads to better factory designs.

What information do I need to simulate a factory design?

Generally, it is the same information that you are using to create the plant design. A process flow diagram (PFD), equipment datasheets and historic production data will provide most of the required data. The gaps can be plugged with best guesses from process experts. The simulation will allow you to carry out sensitivity analysis on key variables, meaning you only spend time and effort on improving accuracy on data that impacts your factory design.

How accurate is a Manufacturing Simulation?

It is as accurate as the data that goes into it. If you are working on the early stages of a factory design, you may be looking at an accuracy of +/- 50%. As your design progresses through the design phases, and the accuracy of your data improves, then the accuracy of the model will improve in parallel.

In my experience, I find that there are two types of information that determine the accuracy of a simulation, individual process parameters (such as cycle times, capacity, start-up periods etc.) and constraints (quantities of staff, equipment, and availability of materials). The use of both of these types of information improves the accuracy of a simulation. For example, if you have underestimated the cycle time of a process, but it is constrained by the availability of labour, the resulting throughput will be more realistic than just using the cycle time on its own. In these cases, errors in the information do not compound.

Why not just create a spreadsheet model?

Sometimes this is easy, and easier is better. If you are working on a single unit operation, or a simple linear series of operations, then a spreadsheet model can work just fine and give you the answers you need. However, for more complex designs a spreadsheet model can get quite tricky, especially where there are:

- multiple unit operations working in parallel,

- complex interactions and decision making,

- large bills of materials and product variations,

- significant material movements and inventory levels to consider,

- complex skill matrix and shift patterns,

- you require production cost for each product or activity (labour, energy and materials).

With this level of complexity, it can be very difficult to convince yourself that you have met a target production capacity, never mind convincing your client. With a spreadsheet model you end up making big assumptions which result in a rough static answer.

This is where Factory Simulation steps in. You can define each part of your complex design separately. Use your data to define the performance of each unit operations, the product manufacturing requirements, the production route, and the resource availability. You then let the simulation software work out the whole design’s performance dynamically.

The dynamic aspect of the calculation lets you check on the plant status at any time of the simulation. If you need to check what is happening at a specific time e.g. Thursday afternoon, you can just skip to that time in the simulation. You can them inspect any element you want, e.g. the current loading of the tunnel freezer. The function helps you make better factory designs, by identifying issues at different stages of production.

At what stage should you create a Manufacturing Simulation?

You can model a manufacturing process at any stage. You can model a concept, a design, or an existing production line. At each stage there will be a different level of accuracy and detail. This is fine because you will be asking the simulation very different questions. For example, at the concept stage you will be concerned about how things fit together, and their sizing required to meet the design brief. With a model of an existing facility, you will have a high level of details such as cycle times and resource scheduling. This is important as you will be asking detailed questions such as how long it will take to make a sales order with a certain product mix.

If you are interested in creating a simulation, take a look at our ‘Factory Simulation: It’s all in the preparation’ article. This article describes how to get a good project scope and starting question for your model.

Simulation at concept stage

At the concept stage you will have limited information, just an idea of how you want the manufacturing facility to work, and what and how much you want to produce. At this stage you may just want to compare different concepts. This will allow you to shortlist the best and take a more detailed look at them. When you have used simulation to identify the right concept, you can add more details and take a deeper look at balance of plant and approximate performance.

It is a good idea at this stage to share the model with your colleagues and clients, and visually show them your ideas. This allows you to gain useful insight about the process and get early buy-in from key stakeholders. As you are only in the concept phase it is quick and inexpensive to make major changes to the design. With a simulation you can respond to feedback quickly, if the changes are simple, you can even make them in the same meeting. This ability to respond quickly, and test recommendations, means you can rule out dead ends and implement good suggestions quickly. This all results in a better factory design and a better outcome.

Simulation at engineering design stage

Once you have an agreed concept you can start producing the detailed design. This information can be fed into the model as it is generated. This will give you a feel for how the current design will perform. The model will also highlight where there are gaps in information, and importantly how sensitive those gaps are to the production facilities performance. Identifying these key pieces of information allows you to develop a technical scale-up plan, using the model you can identify all the key information needed for the detailed engineering. This plan will define the required equipment trials, pilot production runs, and more detail discussions with equipment suppliers.

When the detail design has been completed it can be presented to the stakeholders along with the simulation of the design. This will provide a visual representation of the design that can be interrogated by everybody. This will allow the design to be validated against the design scope and allows the stakeholders to challenge different aspects of the design. Minor changes here can easily be tested and implemented before any concrete has been poured. Again, this results in a better factory design.

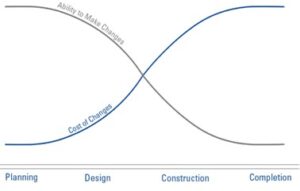

Developing the factory design

This is a good point to develop the design further. An accurate simulation allows you to assess a lot of things that would normally only occur after the facility has been built. And of course, it is much easier to make these changes whilst the design is still on paper. Figure 1 shows the classic cost of change versus the ability to make change as a project progresses.

Areas of the design that you can develop are:

- Reducing capital costs by identifying any underutilised or oversized equipment. Using the model, you can simulate potential plant cost savings and quickly quantify the impact of any change to equipment specifications.

- Finding improvement opportunities by identifying any bottlenecks, wasted resources, or high stock levels. This gives you an opportunity to compress delivery times, reduce operational costs and increase throughputs.

- Cost-benefit analysis on all those optional extras and nice to haves. There may be some real value in adding capabilities at the design stage, instead of ad-hoc changes to an existing plant.

Figure 1. Cost of change versus the ability to make change (www.praxisframework.org).

Development of existing manufacturing facility

Over time markets change. What was once a successful product starts to become less desirable. At this point you may start looking at introducing new products to your production facility. This typically results in changes to production routes, cycle times and possibly the addition of new equipment.

With a model of your factory, you can simulate different product mixes moving through your production facilities. The model will help you determine the economics and throughputs for the new product mixes. And ultimately help you decide what the best product mix is for you, and hence the requirement for development of the factory.

Take a look at our video example of using simulation to determine the throughput of different product mixes.

Calculating operational costs

A more detailed simulation will allow you to measure labour, energy and material usages for different balance of plant. This can be used to generate accurate operational expenditure (OpEx), resourcing needs, and raw materials requirements. This is great as it allows involvement by Finance, Operations, Procurement and Warehousing at a much earlier stage. Early enough that they can suggest changes to the design before it has been finalised.

Generating operational cost data whilst working on plant design allows you to continuously assess the ratio of operational to capital cost of your project. This forces you to achieve the right economies of scale for your design and proves that you are getting good value for money for each unit operation.

Take a look at our video example of using simulation to determine the return on investment for a new piece of equipment.

Determining the factory design resilience

Manufacturing Simulation is not just about getting the most out of your line when things are going well. It is also a way of checking its resilience when it all goes ‘a bit Pete Tong’ (Google it).

Once you have a working model of your plant you can then start adding scripted events, such as breakdowns or accidents. This allows you to work out cost effective equipment redundancy and required repair responses. You can use it to help determine types of service contracts and spares inventory levels. It also allows you to test your emergency procedures to see if they are suitable and sufficient.

One of my favourite examples is shown in the video clip below. There was concern that a breakdown of a materials conveyor would seriously impact the plant’s output. The breakdown of one conveyor had no impact on production. However, it causes a backlog of delivery trucks which resulted in obstruction of the public highway.

Sharing with stakeholders

One of the benefits of creating a factory simulation of your design is that you can share it with all the stakeholders. This visibility helps build confidence and provides you with buy-in from the key decision makers. This can really help you get the project through key stage gates.

Viewing the model allows process owners and operational staff the opportunity to provide useful feedback. I’ve seen seemingly off the cuff remarks from operational staff lead to layout changes that provide a big improvement in operability of a plant. As discussed above, it is much easier to make changes during the early design stage. It can be very frustrating for all, when a good idea cannot be acted on because it came too late in the design stages.

The other benefit is that the model allows two-way conversations. The stakeholders can ask questions of the model. ‘What if we work half day Saturday?’, ‘what if we increase labour on the line?’. We call this the ‘what if game’. Being able to provide immediate answers to what if questions maintains the momentum of the project. It prevents those delays where you have to pause to reforecast your calculation because of a left-field question from the financial manager.

Summary of some of the benefits of manufacturing simulation

Here is a summary of the key benefits of manufacturing simulation that leads to better factory designs.

- Easy to produce a useful simulation of your design. The design process is already collecting most of the information required to create a useful simulation.

- The model provides accurate dynamic information about your design. This allows you to continuously test drive and validate your design against the design specification.

- Produce a technical scale-up plan to support development of the design. Creating a model highlights the key information requirement for the detailed design. This can be used to plan equipment trials, pilot production and supplier conversations.

- Reducing capital costs. Using the model during the design phase, you can identify under-utilised and over-sized equipment, allowing you to confidently reduce the capital costs.

- Identify improvement opportunities. A simulation of a manufacturing facility design, allows your team to identify bottlenecks, wasted resources and high stock levels. This can then be resolved at the design stage, not after the facility has been built.

- Cost-benefit analysis. The benefits of optional extras can be quantified, and real value can be identified early, instead of ad-hoc changes later.

- Determining manufacturing resilience. Using scripted events, you can test the resilience of the production facility against breakdown of key equipment.

- Communicating the design to the stakeholders. The animated representation of your design makes it easy to communicate your plans to stakeholders. Earning valuable buy-in and useful feedback.

Getting started

If you are new to simulation and want to create better factory designs, you can find more information on our Simulation for Design page, or if you want to learn quicker, then contact us for a free demonstration and chat. Remember if you are just starting with simulation in your business, you don’t need to create a fully blown digital twin. You only need to replicate the bits that are important to your questions.

If you think your organisation could benefit by using Manufacturing Simulation, then get in touch for a demo or give us a shout and I can share some case studies.