Often attributed to the management consultant Peter Drucker, this phrase is a constant for me especially when starting out on an improvement project. The importance of measurement, quantifying and evaluating various aspects of a process cannot be stressed enough especially if you want to make meaningful improvements.

But what does this really mean and how can we be sure the data is credible?

Quantification: To improve something, you must first understand and measure it. Quantifying performance, outcomes, or variables provides a baseline for comparison. This quantification can involve data, metrics or other measurable attributes.

Assessment: Measuring and assessing allows you to identify the strengths and weaknesses. You can determine what is working well and what needs improvement. Without measurement, it’s difficult to pinpoint areas which need attention.

Accountability: Measuring something creates accountability. It’s easier to track progress and holds teams responsible for achieving specific goals or meeting defined standards. This accountability encourages effort and improvement.

Feedback: Quantitative measurements provide feedback that helps guide decision-making. It allows you to make data-driven choices and identify effective strategies or necessary changes.

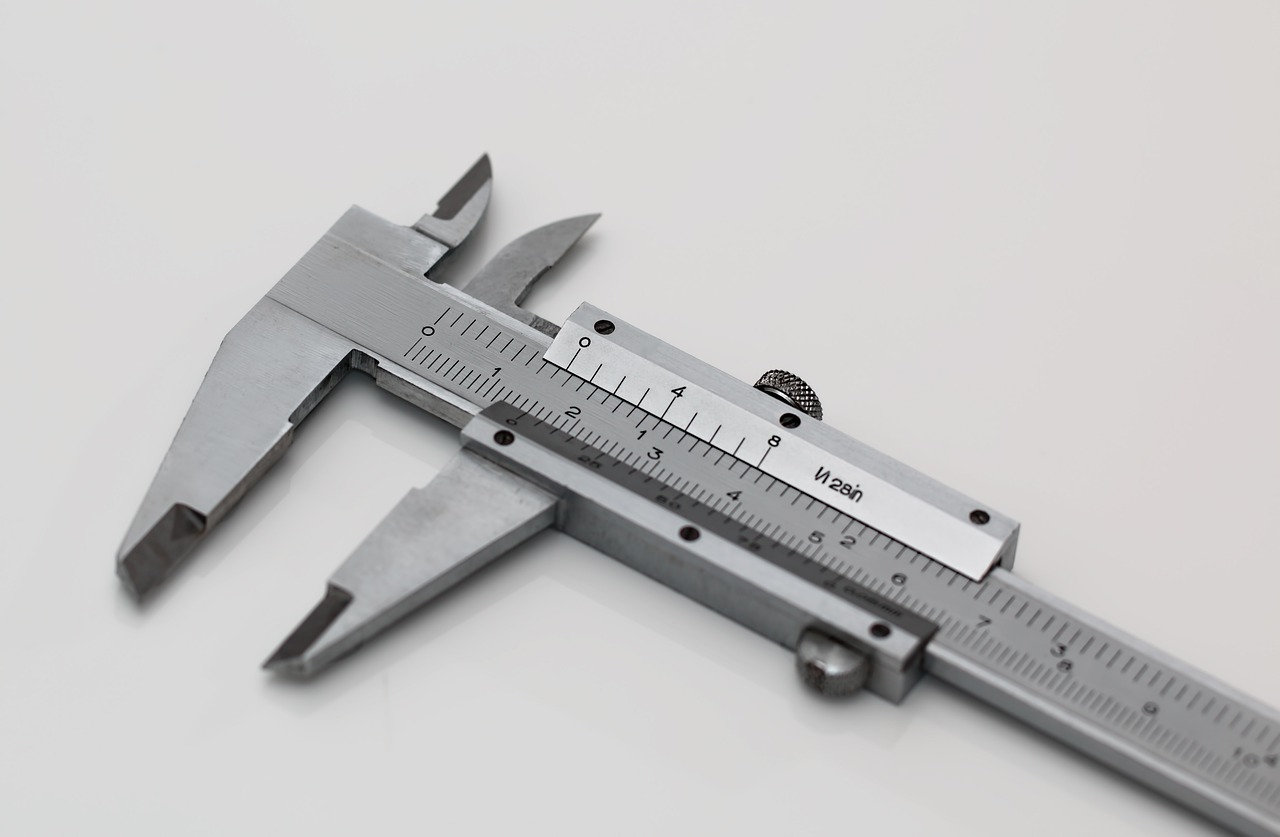

In manufacturing, data is relied on to optimise production processes, minimise defects, and improve product quality. Making sure that the measurement yields accurate and reliable data is also of equal importance and this is where system analysis plays a pivotal role.

Measurement System Analysis

MSA is a critical component of quality control and assurance in manufacturing. It involves evaluating the reliability and accuracy of the measurement systems used in the production process and fundamental making process improvements. A robust MSA helps ensure that the data collected from measurements are dependable and can be used for making informed decisions.

The key aspects of a Measurement System Analysis in manufacturing are:

Purpose:

- To assess the accuracy, precision, and repeatability of measuring equipment.

- To identify and correct issues with measurement systems that can lead to inaccuracies in product quality or process control.

- To determine whether the system is suitable for what you intend to do with the data.

Types of Variation:

Measurement systems can introduce various types of variation which include:

- Bias: The systematic error or offset in measurements compared to a known standard.

- Precision: The random variation or uncertainty in repeated measurements.

- Linearity: Any deviation from a linear relationship between measurements and the true value.

- Stability: Changes in the measurement system’s accuracy and precision over time.

- Resolution: The smallest detectable change in the measurement.

- Repeatability: This is the variation observed when the same item is measured repeatedly under the same conditions.

Gauge R&R (Repeatability and Reproducibility)

Gauge R&R is a method for assessing the reliability of a measurement system. It quantifies the variation in measurements due to repeatability (measurement equipment precision) and reproducibility (variation introduced by different operators or measurement equipment).A high percentage of total variation attributed to repeatability and reproducibility suggests that the measurement system is most likely not reliable.

Measurement Error Sources:

Identify and address potential sources of error, including instrument calibration, operator training, environmental factors, and measurement technique.Regular calibration and maintenance of measurement equipment are essential for ensuring accuracy.

Acceptance Criteria:

Establish acceptable levels of bias, precision, and accuracy for the specific application. Often, industries or regulatory bodies provide guidelines or standards for acceptable measurement system performance.

Measurement System Improvement:

If a measurement system analysis reveals issues, manufacturers can take corrective actions to make improvements, such as recalibrating instruments, providing additional operator training, or upgrading equipment.

Documentation:

Proper documentation of the analysis process is essential. Data, results plus any corrective actions which were taken to improve the system must be logged and recorded.

Statistical Tools:

Statistical methods like ANOVA (Analysis of Variance) and control charts can be used for conducting MSA. These tools help quantify the variation and determine whether it is within acceptable limits.

Continuous Monitoring:

After conducting an initial MSA, it is good practice to carry out regular monitoring to make sure the system is kept within the accepted range. Gift or deviations cn be quickly and easily identified and actions taken to improve and optimise as necessary.

So, the idea behind “If you can’t measure it, you can’t improve it” highlights the importance of data-driven decision-making and the value of quantifying performance to enable improvement. Making sure the measurement system itself is accurate and reliable is critical to drive the right decisions and is a key part of maintaining quality control.

If you want to know more about what to measure, how to measure it and what the data means, get in touch with the team at Production Support 56 for a chat about how we can help or take a look at our webpage, Chemistry Solutions