Blog

The Latest Blog Posts from Production Support 56

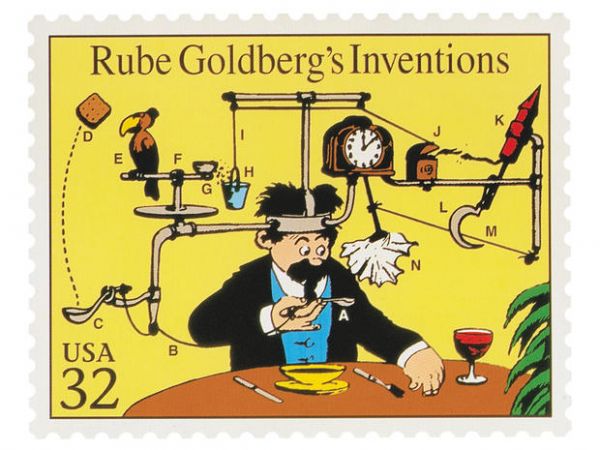

Preventing Mistakes with Poka-Yoke

To focus on improving activities which add value and removing those which do not involves eliminating or minimising the potential for human error and mistakes. This article explores human error, how it impacts the business and how businesses can effectively implement Poka-Yoke to mistake proof and optimise their manufacturing processes and operations.

A guide to making useful Factory Simulations

At Production Support 56 our mission is to cut out the waste and help businesses add value to their production processes by creating useful factory simulations. This can be of an existing factory or a new factory design.

Better Factory Designs with Manufacturing Simulation

Get better factory designs with Manufacturing Simulation. This articles describes some of the important benefits for a Design Engineer to help you produce better factory designs.

Production scale-up: You’re gonna need a bigger bucket

Production scale-up is not always attained by chucking in more resources. You need to accurately understand what you are trying to achieve, find a sustainable solution, then thoroughly implement.

The Science of Choosing the Right Cut – Factors affecting Size reduction

In manufacturing size reduction of materials is possibly the most common activity, Whether its crushing ores in mining, grinding in food manufacturing or fine micronising in pharmaceutical or coatings industries, reducing the size of materials features everywhere.

Constraints in Manufacturing and Simulation: Panic in the airlock

Constraints are an important factor for manufacturing, process improvement and simulation. Constraints are what limit and shape your manufacturing process.

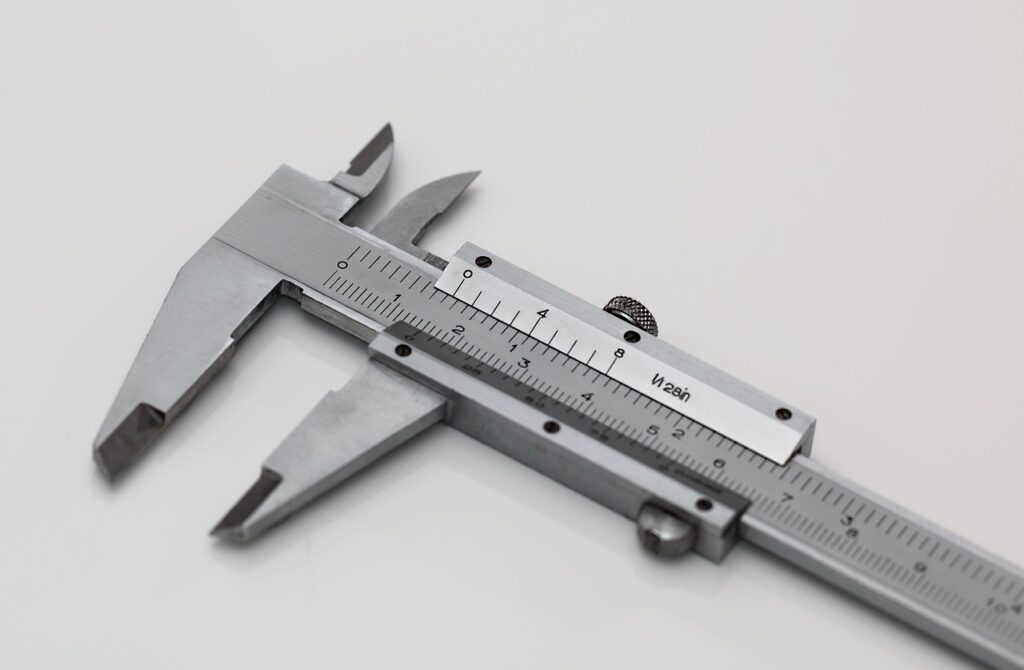

If you can’t measure it, you can’t improve it.

The importance of quantifying and evaluating various aspects of a process is essential, especially if you want to make meaningful improvements. But what does this really mean and how can we be sure the data is credible?

The Essentials of COSHH

Controlling the exposure chemicals in the workplace is not only essential but required by law under the Control of Substances Hazardous to Health Regulations, what we all know as COSHH.

Carrying out a COSHH assessment doesn’t have to be a daunting task if you follow a few simple steps.

Harnessing the power of process mapping to make brilliant simulations

The process map is also the perfect document for starting a factory simulation, it shows you how all the activities are linked together, the workflow and information flow.

What is a process? And the use of SIPOC diagrams.

So, what is a process? From the SIPOC diagram’s point of view it is the supplier and all the inputs that are required for a transformation, the conditions, and steps to undergo the transformation of the object, the product of the transformation and the customer.

Can your design meet the target capacity?

When designing a new factory, production line or manufacturing process, a critical measure of success is demonstrating that the shiny new design fits the brief.

The importance of cleanliness in manufacturing

Cleanliness in manufacturing is an important parameter, not only for hygiene reasons but for quality purposes as well. Hygiene is critical in food & drink, healthcare, beauty, and other service industries.